Parts List

Friend

Find methods for your needs

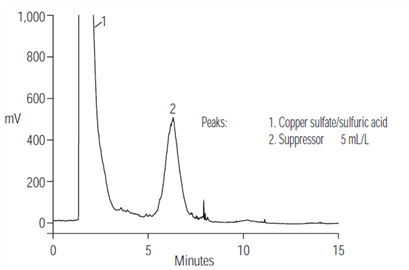

AN145: Determination of the Suppressor Additive in Acid Copper Plating Bath

Description

Copper electroplating systems are used for the deposition of copper on semiconductor wafers. A proprietary suppressor additive is used to influence the quality of copper deposition. Because maintaining the level of the suppressor within the recommended operating range ensures the quality of the fill, we developed a method to determine the suppressor additive. This application note describes the use of the IonPac NS1 column with evaporative light-scattering detection to determine two different proprietary suppressors in acid copper plating baths.| Market: | Material Science |

| Keywords: | Copper Plating Bath, DX-600 Liquid Chromatography System, Enthone suppressor, Evaporative Light Scattering Detector, IonPac NS1, PLS-ELS 1000, Shipley Suppressor, Suppressor Additive, UCI-100 Universal Chromatography Interface |

| Matrix: | Acid copper plating baths |

| Author: | Edward Kaiser and Jeff Rohrer |

| Affiliation: | Thermo Fisher Scientific |

For Research Use Only. Not for use in diagnostic procedures.